Ceramic Jacket Heater Manufacturer

Introduction

Deep Heaters is one of the best industrial Best Industrial Heaters Manufacturer and Exporter founded in Since 2001, have made great strides in the production and export of Thermocouples and All Types of Electric Heaters Wholesaler. We are effectively offering comprehensive heating solutions to various Industrial sectors and other Vertical Industries by using our engineering know-how and decades of experience. utilizing complex machinery and cutting-edge technology. We Provide High Quality Industrial Heaters & We are Manufacturing Customizing Industrial Heaters As per your Requirements.

Heat is frequently the unseen workhorse of industrial processes. For productivity, quality, and safety, exact temperature control is essential when processing chemicals or molding polymers. Additionally, one part that frequently sticks out in the industrial heating industry for its dependability and adaptability is the ceramic jacket heater.These modest but effective devices are used in many different industries to subtly maintain the ideal temperature for machinery.

However, what are ceramic jacket warmers really, and what makes them so popular? We’ll go into the world of ceramic jacket heaters in this extensive guide, covering their design, advantages, uses, and what makes a manufacturer genuinely remarkable. We’ll also highlight Deep Heaters, a business that has made a big impact in this niche industry. We are the best Ceramic Jacket Heater Supplier.

What is a Ceramic Jacket Heater

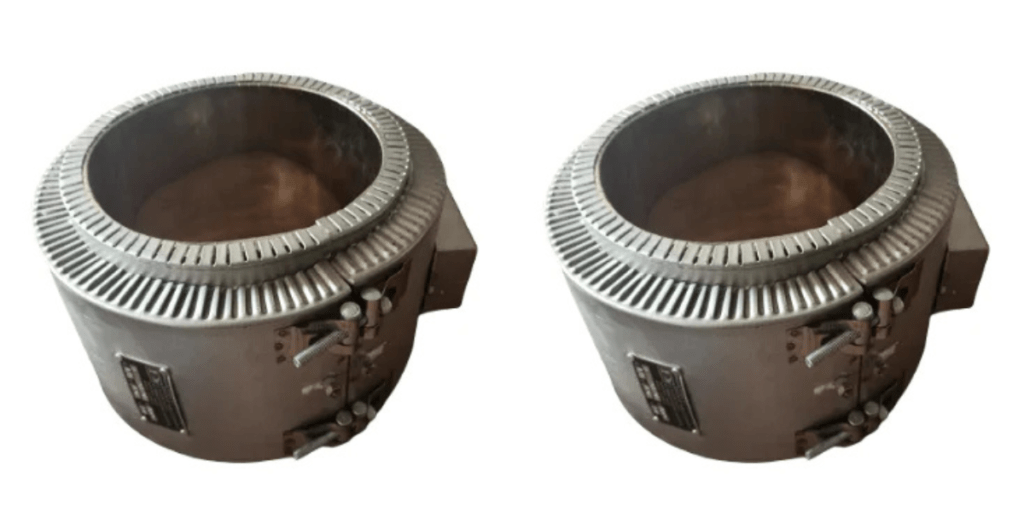

Fundamentally, a ceramic jacket heater is an electrical heating element made to evenly and precisely heat cylindrical surfaces like pipes, nozzles, and barrels. The insulating substance, usually steatite or alumina, which has exceptional dielectric strength and tolerance to high temperatures, is referred to as “ceramic” in its name. A high-resistance heating wire, usually composed of nickel-chrome alloy, is enclosed by this ceramic substance.A protective metallic sheath, usually made of aluminized or stainless steel, which offers corrosion resistance and mechanical strength, is then usually used to house the entire assembly. In order to increase energy efficiency and reduce heat loss, the design frequently includes built-in insulation, such as ceramic fiber blankets. We are the best Ceramic Jacket Heater Exporter.

Why Choose Deep Heaters

Now that you understand the immense value of ceramic jacket heaters, the next crucial step is choosing the right manufacturer. At Deep Heaters, we are not just manufacturers; we are your partners in optimizing your industrial heating processes. Here’s why you should choose us:

- Unwavering Dedication to Quality: For us, quality is the cornerstone of our company and not just a catchphrase. We follow strict quality control protocols from the selection of premium raw materials to the last examination of each completed product. Because of our commitment, every ceramic jacket heater that leaves our factory is sturdy, dependable, and designed to survive the most demanding industrial settings. We take pride in our track record of providing dependable, high-quality services.

- Customization and Tailored Solutions: We are aware that industrial heating is rarely a “one size fits all” situation. Every application has different needs. For this reason, we are experts at creating industrial heaters that are specifically tailored to your needs. Our skilled engineers will collaborate closely with you to design and produce the perfect ceramic jacket heater, regardless of your requirements for shape, size, wattage, voltage, or special environmental factors. This customized strategy guarantees the best possible performance and effectiveness for your particular application.

- Large Experience and Knowledge: Having worked in the industrial heating sector for more than Deep Heaters has a wealth of experience in the development, manufacturing, and distribution of a variety of industrial heaters, including ceramic jacket heaters. Our staff of highly skilled engineers and technicians is equipped to handle challenging heating problems and provide creative solutions. To give you the most dependable and efficient heating solutions, we draw on our decades of experience.

- Modern Manufacturing Plant: We have state-of-the-art equipment and technology in our Gujarat, India, manufacturing plant. We can satisfy the expectations of our expanding clients, maintain constant quality, and retain high manufacturing standards thanks to our sophisticated infrastructure. We consistently deliver high-quality products on schedule thanks to our effective procedures.

- Strong Reputation and Client Trust: Deep Heaters has established a strong reputation for reliability, excellence, and unmatched customer satisfaction over the years. Our long list of satisfied clients from a variety of Gujarati and international businesses is evidence of our dedication to quality work and ability to fulfill our commitments. Selecting Deep Heaters means going with a reliable partner who has a solid track record.

- Continuous Innovation and Improvement: The industrial heating industry is a dynamic one, with ever-evolving efficiency standards and technological breakthroughs. In order to give our customers cutting-edge heating solutions that keep them ahead of the curve, Deep Heaters is committed to continuous research and development, keeping up with the most recent advancements.

- Complete Heating Solutions: Deep Heaters provides a large selection of industrial heating equipment, such as ceramic band heaters, mica band heaters, bobbin heaters, die heaters, cartridge heaters, tubular heaters, and thermocouples, in addition to ceramic jacket heaters. This guarantees smooth integration and support, allowing you to depend on us as a single supplier for all of your industrial heating requirements.

Applications of Ceramic Jacket Heater

- Injection Molding: To make a variety of items, melted plastic pellets are injected into molds. Injection molding machines employ ceramic jacket heaters on their barrels to melt and keep the plastic at the exact temperature required for uniform part creation and smooth flow. Their uniform heating guarantees high-quality molded products and stops plastic from degrading.

- Extrusion: To make continuous profiles (such as pipes, sheets, or films), plastic is melted and forced through a die. Ceramic jacket heaters supply the heat required to melt and preserve the plastic viscosity in the extruder barrel, much like injection molding does.

- Blow Molding: This technique uses precise heat to make the plastic flexible before it is blown into form and is used to create hollow plastic objects like bottles.

- Plastic Welding: To create a robust weld when combining plastic components, the surfaces can be melted locally using ceramic jacket heater heat.

- Heat Sealing Equipment: Ceramic jacket heaters are used in heat sealing bars to produce sturdy, airtight seals on a variety of packaging materials, from medical pouches to food bags.

- Shrink wrapping machines: This method of neatly packing products uses heat to cause a plastic film to shrink securely around the contents. The steady heat required for efficient shrinking is supplied by ceramic heaters.

- Food Warmers and Holding Equipment: Frequently used in industrial kitchens, catering, and buffets, ceramic jacket heaters are great for maintaining prepared food at acceptable temperatures without overcooking or drying it out.

- Baking and Roasting Ovens: Accurate and uniform heat distribution is essential for reliable product quality in industrial-scale baking and roasting.

- Food Extrusion: Ceramic heaters are used in extrusion operations to guarantee the proper consistency when producing certain food items, such as pasta or snacks, much like in plastic extrusion.

Specifications Table Ceramic Jacket Heater

| Parameter | Details |

|---|---|

| Heater Type | Ceramic Jacket Heater |

| Voltage Range | 110V to 440V AC |

| Power Rating | 250W to 10kW |

| Max Operating Temperature | Up to 900°C |

| Insulation Material | High-Density Ceramic Fiber |

| Outer Body Material | Stainless Steel / Aluminum |

| Heating Element | Nickel-Chrome Wire (NiCr80/20) |

| Thickness | 5mm – 15mm |

| Mounting | Clamps, Straps, or Screws |

| Diameter Range | 50mm to 600mm |

| Width Range | 25mm to 300mm |

| Optional Add-Ons | Thermocouples, Insulation Covers |

| Certification | ISO Certified, CE (on request) |

Benefits of Ceramic Jacket Heaters

- Outstanding Heat Uniformity and Distribution: Ceramic jacket heaters are known for their exceptionally uniform heat distribution, in contrast to certain other heating elements that may produce “hot spots.” For procedures that need constant temperatures to prevent material deterioration or product flaws, the interlocking ceramic blocks guarantee uniform heating across the whole surface area. As a result, waste is decreased and product quality is enhanced.

- The capacity to withstand high temperatures is inherent in ceramic materials. Because of this, ceramic jacket heaters can function efficiently at far greater temperatures than many other kinds of industrial heaters, which makes them appropriate for demanding applications in rubber, plastics, and other high-temperature processes. Depending on the design, they can frequently withstand sheath temperatures of up to 900°F (482°C) or even higher.

- Superior Energy Efficiency: More electrical energy is transformed into useful heat because ceramic’s superior insulating qualities reduce heat loss. This directly results in lower energy use and running expenses, providing enterprises with substantial long-term savings. When compared to less effective heating options, many users report energy savings of 25–30%.

- Durability and Longevity: These heaters’ sturdy design, which includes a metal outer jacket and ceramic inner, makes them extremely resilient to vibration and mechanical shock. They have a longer lifespan and require fewer replacements and maintenance because they are made to withstand demanding industrial settings. This results in increased production and decreased downtime.

- Fast Heat-Up and Fast Response Time: Ceramic jacket heaters’ low thermal mass design enables quick response times to temperature changes and quick heat-up times. For processes that need frequent modifications and precise temperature control, this is essential for enabling quicker production cycles and increased operating efficiency.

- Versatile Applications: Ceramic jacket heaters are very adaptable due to their wide range of sizes and shapes, including flat panels, cylindrical, and custom designs. They are frequently utilized in.

- Improved Safety Features: Reputable manufacturers frequently add safety features like tip-over switches and overheat protection, which further improves the ceramic jacket heaters’ safety profile, particularly in industrial applications where safe and dependable operation is crucial. An additional layer of safety is provided by the ceramic material’s poor electrical conductivity.

Types of Ceramic Jacket Heaters

1. Ceramic Band Heaters

- These are circular heaters made for heating cylindrical surfaces such as barrels, drums, and injection molding machines. They are available in split or one-piece designs, depending on your installation needs.

Features:

- Energy-saving insulation

- High watt density

- Built-in thermocouples (optional)

2. Ceramic Nozzle Heaters

- Nozzle heaters are specially made for heating nozzles of injection molding machines. They ensure precise heating at the output point.

Features:

- Compact size

- Fast heating

- Long lifespan

3. Flexible Ceramic Heaters

- These heaters come with flexible ceramic fiber layers for easy installation on irregular or large surfaces. Ideal for curved or angled applications.

Features:

- High flexibility

- Lightweight design

- Even heat coverage

4. High-Temperature Ceramic Heaters

- These are premium-grade heaters that can operate at very high temperatures, up to 800°C or more. They are used in high-demand industrial zones.

Features:

- Excellent thermal insulation

- High durability

- Multiple mounting options

5. Infrared Ceramic Heaters

These are designed for infrared heating applications, where fast and focused heat is required.

Features:

- Energy-saving IR heating

- Available in different wavelengths

- Fast start-up time

Conclusion

Although they may not be the most glitzy parts of an industrial facility, ceramic jacket heaters are crucial. They are the unsung heroes that make it possible for innumerable production operations to function smoothly, accurately, and efficiently. They are an essential component of contemporary manufacturing because of their remarkable endurance and capacity to deliver high, steady heat. We are the best Best Ceramic Jacket Heater Manufacturer.

Selecting the appropriate manufacturer is crucial when it comes to getting these essential parts. Within the industrial heating industry, Deep Heaters is a shining example of quality, knowledge, and client dedication. They are the perfect partner for any company looking for dependable and effective heating technology because of their commitment to creating high-quality ceramic jacket heaters, as well as their extensive selection of heating solutions and unwavering customer service.