Ceramic Band Heaters

Deep Heaters is the Best Ceramic Band Heaters Manufacturer & Exporter in India. Ceramic band heaters are designed with spirally wound inner resistance coils evenly threaded through interlocking insulated ceramic “tiles”. The ceramic core, or “mat” of tiles is housed beneath a stainless steel sheet with serrated edges. The notched edges fold over to secure the ends and a protective inner liner (to be removed at installation) secures the placement of the tiles. This combined assembly of the Ceramic Band Heater offers a flexible heating system that yields efficient transmission of conduction and radiated heat. The heat of the Ceramic Band originates from the inner coils that conduct heat at maximum temperatures.

The heated coils of Ceramic Band Heater evenly deliver heat through the ceramic tiles which radiate energy to the barrel. We offer a variety of Ceramic Band styles from standard to custom configurations.

Ceramic Band Heater Capabilities and Benefits:

- Built in insulation minimizes unwanted change in temperature along the barrel.

- Efficient heat transfer: Heat transfers through radiation, conduction, and convection, so a perfect fit is not required compared to other Ceramic band heaters.

- Heat transfers are not affected by irregular surfaces or a loose fit.

- Because they operate at higher watt densities, they can be used in wider increments.Because they operate at higher watt densities, they can be used in wider increments.

- The number of bands used can be reduced with simplified wiring.

- The heater is safer with the cooler external surface – over other band heaters.

- The flexible design allows easy install and removal.

Ceramic Band Applications:

Extruders, Injection molding machines, Blown film dies, and other cylinder heating applications.

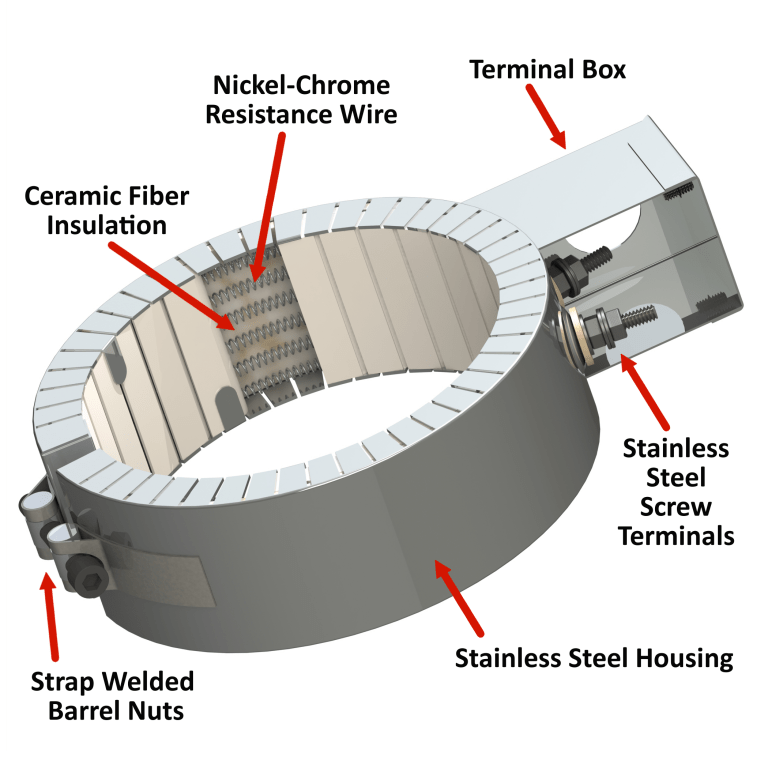

Construction:

Stainless Sheath-

AlthoughSS 304 stainless steel is also an option depending on application requirements, we typically use aluminium coated sheath for oxidation resistance in a variety of environments.

Screw Terminal-

Screw terminals for maximum amperage carrying capacity and a firm connection with the winding.

Terminal Box-

Toshield terminals from spillovers and leaking and to safeguard against exposed terminals. Various terminal types are used, including SS bolded terminals and crimp on lead ceramic connector types with copper lug crimping.

Resistance Wire-

Resistance wire made of 80/20 nickel-chrome and copper is uniformly coiled for long heater life.

Ceramic Fiber Insulation-

Because they can tolerate high temperatures, ceramic fibres are employed as insulation materials.

Ceramic Nuckles-

High purity aluminumoxide ceramic knuckles having maximum dielectric strength and thermal conductivity and finely compacted for maximal heat transfer were selected for the winding process of the heating element.

Pros of mica bands over ceramic bands are as follow:

- Mica bands can typically achieve equal or higher watt density than ceramic bands for operating temperatures in the range required for the plastic industry.

- Mica bands are thin, typically between 0.12" and 0.19" thick. Ceramic bands are usually between 0.40" and 0.75" thick.

- Mica bands are cheaper than ceramic bands and lighter.

- When properly de-rated, ceramic bands can achieve higher operating temperatures.

- Ceramic bands can be repaired, which involves replacing the ceramic assembly and reusing the rest if undamaged. Our prices are 30% cheaper than for a new band with the same lifespan and can also be repaired multiple times.

Such factors decrease the heat transfer and operating life of mica bands but have next to no effect on ceramic bands that really are heating in the air.

At first glance, Ceramic Band Heaters Manufacturer, but the ease of installation of ceramic bands cannot be overstated. Over time, machines often become dirty and damaged, the surface becomes rough, which can lead to improper installation (air pocket between the band and the barrel). The result is poor contact with the surface to heat. Those factors reduce mica band heat transfer and operating life, but have next to no effect on ceramic bands which are heating the air.